Effective food allergen management is essential for protecting the health and wellness of at-risk consumers. Everyone who works in the food industry has a responsibility to understand the seriousness of food allergies along with their role in the allergen management process.

In this guide, gain insights into the identification, assessment, management, and verification of food allergens. Regulatory and 3rd party certification requirements are also discussed along with allergen testing methods.

Table of contents

- What is a food allergen?

- Examples of common allergens

- Food Allergen Recalls

- Food Allergen Regulations

- What is Allergen Management?

- 3rd Party Certification Audit Requirements

- Food allergen hazard analysis

- Allergen cross-contact

- Testing for food allergens

- Allergen Management Training

- Guidance tools for Allergen Management

What is a food allergen?

Before managing food allergens in the food industry, you need to know what a food allergen is. A food allergen can be defined as being a protein that is found in food that is capable of triggering a response in individuals sensitised to it. As a collective term, food allergies and food intolerances can be unpleasant, complicate life and in the worst cases, are fatal. The cause of food allergic disease is still not fully understood. However, there is general consensus amongst scientists and clinicians that the cause is linked to a combination of Western lifestyle, environment, and genetic predispositions.

Examples of common allergens

Some common food allergens include crustaceans, eggs, fish, milk, peanuts, soy, tree nuts, sesame, lupin, mustard, celery and cereals containing gluten.

Food supplements such as bee pollen, Royal Jelly and propolis also cause allergic reactions, as well as non-food items such as latex, cosmetics, and medications.

There may be other allergens that have not been listed which are applicable to your country of manufacture.

Foods causing allergic reactions

While any food can cause an adverse reaction, there are eight types of foods that account for about 90 percent of all reactions. These include Eggs, Milk, Peanuts, Tree nuts, Fish, Shellfish, Wheat, and Soy.

Certain seeds, including sesame and mustard seeds (the main ingredient in the condiment mustard), also are common food allergy triggers and considered a major allergen in some countries.

Food Allergen Recalls

There is plenty of evidence to support that undeclared allergens are one of the greatest causes for food recalls worldwide. Here are the latest allergen recall-related statistics for major reporting agencies around the world.

International Statistics for 2019 and 2020

| REPORTING AGENCY | YEAR | % of undeclared allergen recalls to total recalls | Number of Undeclared Allergen recalls / Total Recalls |

| FSANZ, AUSTRALIA | 2020 | 46.7% | (51/109) |

| USDA, USA | 2019 | 25.8% | (32/124) |

| FDA, USA | 2020 | 51.9% | (188/362) |

| FSA, UK | 2019 | 65.3% | (115/176) |

| RAFSS, EUROPE | 2019 | 4.7% | (194/4118) |

To learn more about the common reasons for food allergen recalls and what you can do to protect your food business click here.

Food Allergen Regulations

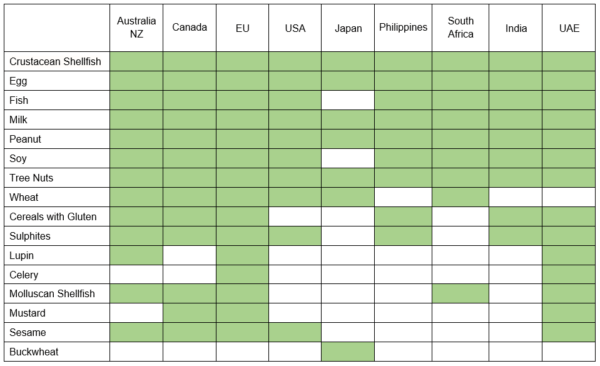

There are strict laws in most countries relating to labelling of allergens and non-compliance due to cross-contact. Depending on where you are located, different types of allergens are required to be declared on the packaging or for unpackaged foods – advised to the consumer on request.

Here is a comparison of food allergen labelling regulations for different countries.

By complying with the relevant legal circumstances and implementing best practice allergen management, you will enviably protect yourself, your food business, and the consumer who has issues with food allergens.

Precautionary Labelling

Some countries allow precautionary labelling. ‘Advisory’ or ‘precautionary’ allergen labelling is a statement on the label of a packaged food to advise the purchaser, or the consumer, that the food has the potential to contain one or more allergens, which are not intentionally added as ingredients in the product

Precautionary labelling should not be seen as fall-back for poorly implemented GMP.

What is Allergen Management?

Allergen Management is a system of policies and procedures that serves to identify, control, educate and communicate the risk and presence of food allergens in your business, from raw materials through to finished products.

All of these procedures, or SOPs, should be developed, documented, implemented and maintained as part of the Allergen Management Program for your business. An effective allergen management program will provide structure around identifying allergen risks within your business and also contributes to exercising due diligence.

Understanding food allergies

There is currently no cure for food allergy, nor are there any firm conclusions regarding the number of food allergens needed to trigger an adverse allergic reaction. It really does depend on the individual food consumer. The only way to manage a food allergy is by avoiding the food allergen.

As a food company, you will need to operate to ensure a nil detection in any food that is produced or manufactured. This is vitally important especially if you make a food claim that your food product does not contain particular food allergens.

3rd Party Certification Audit Requirements

If your business is certified against a recognized GFSI (global food safety initiative) standard, it will be a requirement to have an allergen management program documented and implemented within your business. This program should include:

- Procedures to control Allergens and prevent cross-contact

- The identification of allergen risks in raw materials, finished products and at each step in the process

- The allergen status of materials used in plant / equipment maintenance and cleaning

- Acceptable and unacceptable cleaning performance limits

- An assessment of cross-contact allergen risk

- Procedures to verify allergen labelling

- A list of allergen-containing materials handled on site

- Systems to restrict the movement of airborne dust containing allergenic material

- Restrictions on food brought onto site by staff, visitors, caters and contractors Allergen awareness and allergen handling training

This is not a comprehensive list. It is advised to refer to the applicable GFSI recognised standard or mandated customer requirements. You can also refer to the HACCP Mentor post on “How to develop an effective allergen management program”.

Codex Alimentarius adopted the Code of Practice on Food Allergen Management for Food Business Operators (CXC 80-2020) in 2020. This Code aims to provide a harmonized understanding of food allergens and their management by food business operators. You can download a copy of the Code by clicking here.

Food allergen hazard analysis

Codex HACCP requires that potential hazards be identified and then evaluated to determine which are significant. It also recommends that the source or reason for presence be described. The HACCP team needs to have a good understanding of where allergenic food hazards originate. To get you started, here is a list of some potential sources:

- Raw materials (including processing aids)

- Processing Equipment and utensils

- Chemicals used for cleaning and maintenance activities

- Food handlers

- Personal protective equipment (PPE) e.g., gloves

- Work-in-progress

- Food packaging

- Staff vending machines

- Finished products

After completing the hazard analysis if any potential food allergen was found to be significant you would then need to implement an applicable control measure or preventive control.

NOTE

When completing your hazard analysis make sure to include ingredient samples and materials used during any research and development (R&D) activities.

Allergen management preventive controls

There are various methods, practices and controls which can be implemented by your food company to support effective allergen management. These include:

- Knowing and identifying the allergen status of all raw materials and finished products you handle

- Implementing allergen-specific Good Manufacturing Practices

- Labelling products correctly with correct ingredient statements and allergen information

- Educating all staff in allergen management procedures

Check out additional preventive controls by clicking here.

Classifying food allergen hazards

Food allergens have been traditionally classified as a chemical food safety hazard. With the severe impact that they can cause to at-risk consumers, it makes sense to identify food allergens as their own category. This would then allow you to classify potential food safety hazards as either biological, chemical, physical or allergenic.

To learn more about methods of identifying food safety hazards check out The Ultimate Guide to Food Safety Hazards.

Allergen cross-contact

Cross contact of food allergens is similar to cross-contamination in regards to food safety. It may occur during all steps of a process where product or materials are exposed including preparation, food handling or food service.

Cross-contact happens when one food comes into contact with another food and their proteins mix. As a result, each food then contains small amounts of the other food. These amounts are so small that they usually can’t be seen.

Even this tiny amount of food protein has caused reactions in people with food allergies! To learn more about cross-contact and how to avoid this issue in your business check out our article on ‘How to prevent food allergen cross contact’.

Considering unknown food allergens

Unknown or unintended allergens can be introduced into your food business in many ways. This can become a major issue especially if your food production or retail site does not handle allergenic materials or produce allergenic products.

Sources of unknown allergens

When looking to prevent unknown or unintended allergens, it is a good idea to identify potential sources. These sources can be grouped into either:

- Supplier origin

- Contract manufacturing or handling

- Employees

- Visitor or contractor activities

The average food business will be exposed to at least three of the above four risk sources.

Mitigating the risk of unknown allergens

It makes it extremely hard to mitigate risk correctly when the actual risk cannot be identified. In the case of unknown food allergens and the sources previously mentioned, education and training will be your best defense. Ensure that all food handlers, contractors and visitors have a basic understanding of food allergens and effective handwashing.

The Allergen Bureau have recently updated their ‘Unexpected Allergens in Food’ guide. You can download a copy by clicking here.

Testing for food allergens

Food allergen testing helps to provide a level of assurance and verification, especially when you have allergens as a critical control point. Testing should not be seen as a substitute for ensuing that fundamental allergen management practices are in place within your business.

The purpose of completing allergen testing maybe to verify that cleaning has been effective in-between the handling or manufacture of allergenic and non-allergenic products.

It may also be used to support label health claims made about a product or to identify undeclared allergens in raw materials. Whatever your reason please make sure that you understand the capability of the allergen test kit being used.

Allergen analysis tests

Allergen analysis tests have different methods of detection and potential limitations. It is important to understand the requirements of allergen testing so that the correct test can be used. Above all, whichever technique you choose, it should be fit for purpose. You may need to engage a skilled analyst to provide guidance in choosing a fit for purpose analysis technique and appropriate sampling.

Common food allergen analysis techniques

There are several different types of analysis techniques available for use. These include:

- Enzyme Linked ImmunoSorbent Assay (ELISA)

- Lateral Flow Devices (Strip Tests)

- Adenosine Triphosphate (ATP Swabs)

- Polymerase Chain Reaction (PRC)

- Mass Spectrometry

- Biosensors

Each of these techniques are different and may not necessarily produce comparable results.

Can ATP Test kits identify allergens?

A common question I get asked is “Can ATP Test kits identify allergens?” The Allergen Bureau advises that:

“ATP (Adenosine Triphosphate) test kits are less sensitive than specific allergen tests. They detect ATP from all sources (animal, vegetable, microorganisms, food protein residues etc) and are a general indicator of sanitation.

ATP test kits and protein swabs indicate general hygiene, as they are not specific to allergen residue, nor representative of allergen load. All swabbing may be impacted by sanitisers or residues and swabbing in general is qualitative and can only be used in easily accessed areas, so results may not accurately reflect the risk associated with hang up or closed systems.”

Allergen Management Training

Codex recommends that “all relevant personnel in a food business should receive food allergen training as appropriate to their job responsibilities, so they can contribute to the measures needed to prevent or minimise the likelihood of allergen cross-contact and labelling errors.”

HACCP Mentor offers a suite of training courses to help manage food allergens and meet relevant compliance requirements. Our most popular courses include:

- Understanding food allergens – Express Learning

- Allergen Awareness

- VITAL® Online for Allergen Management

You can view our allergen training courses by clicking here.

Guidance tools for Allergen Management

There have been some recent guidance tools released to help food manufacturers with understanding, managing and implementing allergen management in their food business. Depending on your location check out the following links: