The foundation of HACCP is based on identifying everything that can go wrong (hazards) with regards to food safety and your products and processes. When you have done this you can then put a strategy in place to stop or reduce (to a safe level) the food safety hazard from occurring.

In this guide, learn about what a food safety hazard is, how to identify and document them, how and where to source hazards relevant to your business and industry sector.

Table of contents

What is a Food Safety Hazard?

Food companies are not generally in the business of hurting their customers. Therefore, having a full understanding of “what can go wrong” with the food that you produce or handle is essential. It is useful to first understand what is a food safety hazard.

A food hazard can be defined as being any biological, chemical or physical agent, found in food, that has the potential to cause harm, injury or illness. Food safety hazards may occur naturally, be unintentionally introduced or intentionally introduced.

Identifying hazards in your business

You may be thinking – Why do I need to identify food safety hazards? Firstly, it makes good business sense. The worst-case scenarios for not identifying and controlling food hazards adequately are food poisoning outbreaks, product recalls, regulatory action and potential damage to your brand.

Another driving force behind the requirement to identify food safety hazards is to comply with Codex HACCP and GFSI recognised standards. Hazard identification is a fundamental requirement of HACCP Principle 1.

Many different food laws across the globe stipulate the need to identify potential food safety hazards in your food business. If your food business is located within the USA, food safety hazard identification is a requirement of FSMA. The requirement states that a food business is to identify hazards that are known or reasonably foreseeable.

Food safety hazard categories

Potential hazards are required to be identified at each step in your process, for all of your raw materials and for each type of food your business manufactures, processes, packs or holds. Food safety hazards can be categorised as either:

- Biological

- Chemical

- Physical

Depending on your customer requirements and county of manufacturing, you may also be required to specifically identify radiological and allergen hazards separately. Traditionally, allergens and radiological hazards have been classified as a ‘chemical’ hazard.

Biological Hazards

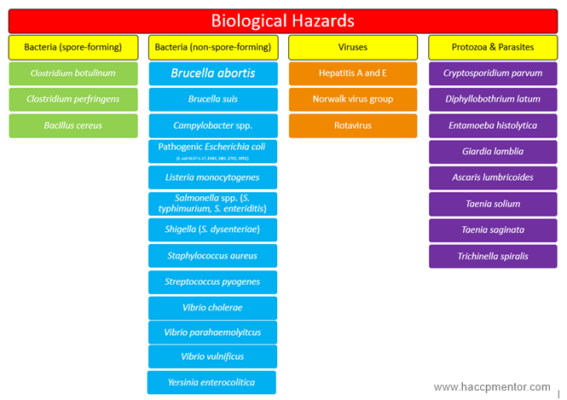

The potential for biological hazards, including microbiological hazards such as parasites, environmental pathogens, and other pathogens must be identified. The FDA’s Bad Bug Book is a great reference that provides current information about the major known agents that cause foodborne illness. To access this book please click here. Some common examples are shown in the image below.

Chemical Hazards

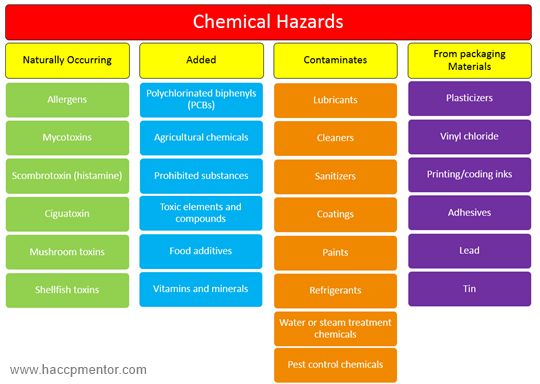

A chemical food hazard as defined by the FDA regulation on cGMP, Hazard Analysis, and Risk Based Preventive Controls for Human Food, is any chemical agent “that has the potential to cause illness or injury”. Food chemical hazards can be classified into any one of the following three groups:

(1) Chemicals that occur naturally

(2) Chemicals that you may use in the formulation of your finished product

(3) Chemicals that are unintentionally or incidentally present in your finished product or packaging.

To learn more about each of these different types of chemical food hazards and how you can assess them within your food business check this post on How to identify chemical hazards in food.

Physical Hazards

Physical hazards can come from a variety of sources including from people, plant, the actual product, packaging and the manufacturing or food-handling premises. This is a definite area to avoid hazard grouping and analysis as different physical hazards will have different likelihoods but more importantly different consequences or severity.

Identifying specific food safety hazards

There is a common misconception that it is suitable to just identify different hazard categories. Codex does not promote this undertaking but rather the identification and assessment of specific hazards. Based on this definition and logic, individual hazards, not hazard categories, are to be identified.

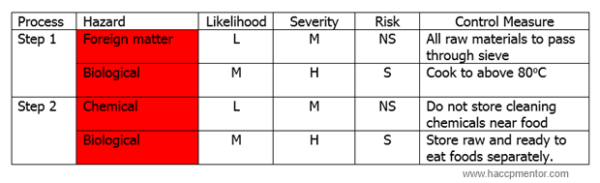

The following graphic shows the incorrect identification of hazards (by category) in a HACCP plan.

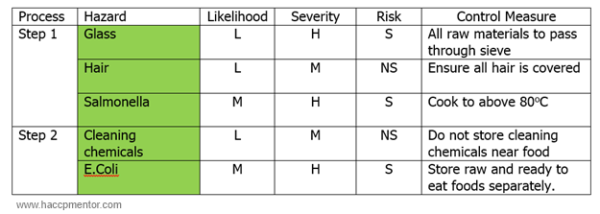

Individual food safety hazards (or specific hazards) are required to be identified. The graphic below demonstrates the correct identification of specific food safety hazards.

Methods to identify hazards

Food safety world-wide is moving towards prevention rather than reaction. But before we can prevent food safety issues, we first must understand what could possibly go wrong. It is this level of knowledge that is lacking in many food businesses today. Working out or having knowledge of all the things that can wrong in your food business is known as hazard identification.

When you undertake the process of hazard identification, you must do so based on your own experience, on illness data, from scientific reports and from other information. So, how do you work out what hazards could occur in your business? There are many different methods but here are a few to get you started.

1. Review customer complaints

Customer complaints are a valuable tool when identifying hazards in your food business. These easily identify things that have gone wrong in your business as identified by your customers. Every customer complaint should be reviewed to identify the hazard, type of hazard and source of the hazard. You can also review if your food business has been involved in any food recalls or withdrawals.

2. Brainstorm with your team

Tap into the knowledge and experience of your own HACCP team and food production staff. Some of your employees may have worked for other food businesses and can recall things that went wrong or “hazards”. Talk to staff who have worked in the business for a long period of time. There may be memories of things going wrong or issues that contributed to them having a really bad day.

3. Review food recall databases

Many government departments around the world will publish alerts for food products that are under recall from the marketplace. Have a look at the different databases to find out what products are being recalled and why they are being recalled.

Regulators may also publish a “Name and Shame” list of food businesses that have been prosecuted or fined. Researching the detail of these listings can also help you to identify potential food safety hazards in your business.

Just remember, if your food business hasn’t had a food recall or been fined for a particular issue, doesn’t mean it won’t happen in the future.

4. Research industry based journals and technical information

Industry bodies can be a good source for identifying issues that face your industry as a whole. Scientific information around food poisoning hazards is also available from your testing laboratories, public health departments of government and universities.

Documenting your food safety hazards

Food hazard identification must be documented as part of the hazard analysis process. The way that you format this is entirely up to you, as long as it is documented. For my consultancy clients, I tend to document the hazard analysis (including food hazards) using a word document or excel spreadsheet.

Resources to help your food business

Our courses, templates, webinars and workshops are designed to help you grow your knowledge, enhance your skills and comply with food safety hazard identification requirements.

The process of hazard identification and analysis is comprehensively covered in our HACCP Principles and Application online course and our FSPCA Preventive Controls for Human Food Blended Course

Templates to help you document your food safety hazard identification process can be found here, and for raw materials, here. Full HACCP Program templates can be found by clicking here.

Really helpful. I do have a couple of couple queries though:

1 – why are mycotoxins chemical and not biological hazards?

2 – given the importance of allergens, why are they not in a hazard group of their own?

Thanks for your comment Carol. For your mycotoxins question please refer to the FDA Guidance on Chemical hazards.

For your second question on hazard categories – I think they should have their own hazard category. Many of the GFSI standards will state as much and so do certain regulatory requirements (depending on where you are located). Codex still states the 3 categories when undertaking a simplified hazard analysis.

Clear, informative and useful. Thank you for sharing this.

You are most welcome Shona. Thanks for adding your feedback.

Thanks dear with amazing work

You are welcome Rosemary

Thank you for this insighful article and resources Amanda. It’s a great refresher too. In our company, we highly value your articles and training courses. Keep up the excellent work of supporting food safety industry professionals.

Thankyou Ruth and thanks for being an active member of the HACCP Mentor community. I always appreciate your feedback, insights and contributions.

Good job Amanda

Thanks Ahmed!

Excellent and useful article as always.

Thanks Kathy, I hope you are doing well 🙂

Thank you Amanda for this useful article.

You are very welcome Ndeye

Very simple but helpful. Straight forward message and communication. Love this

Thanks Norman. I am glad you found this post useful.

As always, great information and laid out in a user-friendly style with links!

Thanks Brit 🙂 I appreciate your support.

Useful! Thank you.

You are very welcome Carol!