Product testing is an integral part of your food safety management system and serves to verify that your food business is producing food safely. In this post find out what you should include in your product testing documentation along with how to determine the testing limits for common microbiological and chemical contaminates.

Product Testing Elements

If your business is certified to an GFSI recognised standard, checking the standard for requirements is you first port of call. If not, at a minimum, your product testing requirements should include:

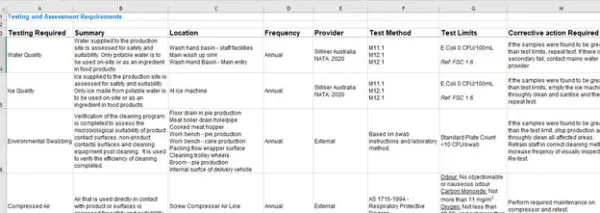

- Testing Required – For example Water quality, Environmental Swabbing, Sensory, Microbiological, Chemical, Product shelf-life

- A summary of why the testing is being performed

- The location of where the testing will take place

- The frequency the testing will occur

- The name of the provider – this is the person who will complete the analysis. This may be an external food testing laboratory or your own in-house laboratory if you have one.

- The test method to be used. Try and tie this back to an international or recognised testing standard if possible.

- The test limits – these determine the parameters of compliance. For example, Listeria species is Not Detected per 25g, Bacillus cereus < 100 cfu/g

- Corrective Action – If a result shows a non-conformance against the allowable testing limit, detail what will be done to rectify the issue.

Keep within Legal Limits

Depending on where you are located, there may be legal test limits that apply to the products that you produce. You will need to do a little bit of research of your local food laws to see what they are. Here is a great resource published by FSANZ to get you started. It also provides plenty of international links to point you in the right direction. You can also refer to your preferred external testing laboratory to provide guidance on acceptable limits for microbiological, pesticide, heavy metal or other chemical contaminates.

How to document your food product testing requirements

For my consultancy clients, I tend to use an excel spreadsheet to document all of my testing requirements. This is different to a verification schedule which is designed to incorporate other system testing that is required by the business, for example, internal audits, GMP audits, mock recalls etc.

Label each of the columns with a different analysis element (as listed above). You can see an example below.

Wrap Up

Product testing is an essential part of ensuring food safety and should be a priority for any food business. Documentation is critical in this process and should include testing requirements, the reason for the testing, testing location, frequency, provider, test method, test limits, and corrective action plans. It is also important to keep within legal limits and refer to external testing laboratories when necessary. By following these guidelines, you can ensure that your food business produces safe and high-quality products.

Share your Knowledge

Do you have a great reference that you turn to when deciding what you should test your food products for? Share the love with the HACCP Mentor community by leaving a comment below.