Mass balance, in relationship to food production, can be defined as being the ability to account for all quantities of raw materials, waste, work-in-progress and finished product. Correct calculations ensure that, in the event of a recall, you can account for all potentially affected raw materials and finished product. In this post, find out the key elements that you need to consider when undertaking and documenting mass balance.

Traceability Relationship

Mass balance has a direct relationship with traceability. So, in saying this, you need first to have a clear understanding of how the product is traced through your food production system. Start with inputs and finish with outputs. I find it helpful to draw a map of the process flow.

Weight Management is key

Mass balance is all about quantity in the form of weights and measures. You need to know the weights of:

- Ingoing raw materials or inputs

- Process gains or losses

- Waste

- Rework

- Production / Quality Testing Samples

- Finished product

- Customer Returns

If you don’t specifically know the weights of each element listed above, trials may need to be established to collect this information. A food business that has a good grasp on their production processes and costs will be better positioned to achieve a total and equal mass balance.

Consider packaging

Many of the current GFSI recognised standards require packaging and labels to be part of any mass balance calculation. These are commonly overlooked area for many food manufacturers. Ensure that you consider direct contact packaging, shippers, security ties and adhesive food labels.

Mass Balance Records

Like many of your other food compliance requirements, you need to be able to evidence that your food business can successfully achieve mass balance. Records need to be maintained to clearly show the weights (loss and gain) of each considered element at different process steps.

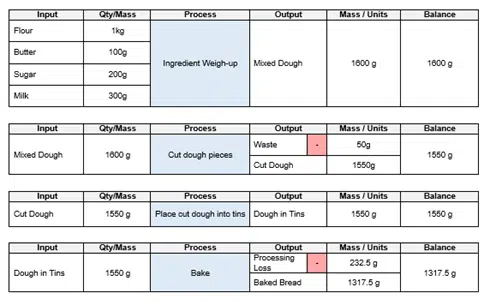

It is helpful to visualise at what step in the process you need to record mass information. Do this by documenting the inputs and outputs to each of your flow process steps. Here is a straightforward example using four subsequent process steps.

Using the case in the image above, you would need to record:

- The ingoing raw material weights and the total weight (sum) at the “Ingredient Weigh-up” step.

- The weight of the waste at the “Cut dough pieces’ step.

- The final weight of the baked bread

With this core information captured, you can then easily calculate the mass balance.

Variation Warnings

Due to the nature of food manufacturing, there will always be variations. Record the exact weights at each relevant process step and not guestimates. A case in point is for raw material weights. Just because it states 1 kg on the ingredient bag does not mean there is 1 kg in the bag.

Test your system

Test your ability to determine the mass balance regularly. Many businesses will do this as part of completing a mock product recall. I suggest completing several standalone mass balance activities, on each of your different products, to ensure your capability.

How good is your food business?

Is your business able to perform a 100% mass balance? If not, what are your challenges? Share your insights with the HACCP Mentor community by leaving a comment below. To learn more about mass balance, check out HACCP Mentor’s online course on Food Traceability Principles and Implementation.