In episode 23 of HACCP Mentor Review find out about the importance of critical limit validation along with documenting your own microbiological acceptance table.

Watch Now

Welcome to Episode 23

Thanks for joining me this week for HACCP Mentor Review Episode 23. This week we cover micro acceptance tables, completing pest bait audits, the importance of critical limit validation and a the final results of two recent food poisoning outbreaks.

How to develop a Micro Acceptance Table

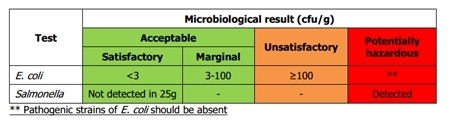

Any good food safety system will include a verification activity that involves having your food product tested for the presence of microbiological contamination. Getting the product tested is easy, but an area sometimes neglected is checking to see if the reported results are ok or not. This is where a micro acceptance table comes in handy.

These tables should be developed to reflect the types of food tested and the limits of acceptability for each of the testing criteria’s. Reference to applicable regulatory limits should also be incorporated in what you determine to be acceptable.

Procedures should also be documented outlining what should be done if the testing results are marginal, unsatisfactory or potentially hazardous.

Food Poisoning Outbreaks

The Centers for Disease Control and Prevention have in the past week released final updates on two different multistate food poisoning outbreaks which occurred in the USA. The first involved two separate strains of Salmonella infection linked to Tahini Sesame Paste and the second involved 84 people infected with Salmonella Saintpaul linked to imported cucumbers. You can check out the final reports from the links on the HACCP Mentor Website.

Tahini Sesame Paste Food Poisoning Outbreak

Imported Cucumbers Food Poisoning Outbreak

Action Item

This week’s action item is to check that all chemical containers are labelled. This includes any spray bottles that chemicals have been decanted into. The purpose of this activity is to make sure that all chemicals can be easily identified.

Pest Bait audits

Pest control bait maps are documented to depict the type of control and the location of the control. Common pest control devices include rodent traps, electric fly killers, sticky baits and moth pots. Make it a pest control verification activity to routinely go around and compare the physical location of these devices against what has been documented on your pest control bait maps. Also check the security and condition of your bait stations during these audits.

The importance of critical limit validation

All critical limits that you have identified and allocated in your HACCP Audit table need to be validated. This means you need to be able to say where did you get the critical limit from and what evidence or justification supports that it is going to work to achieve the desired food safety outcome.

Critical limit validation can be either based on process validation (where you have done the validation study yourself) or from theoretical validation (where you reference legislation or other recognised information). You are required to document all validation sources for each critical limit. The easiest way to do this is draw up a ‘Critical Limit Validation’ table with three columns. In the first column title it ‘Process Step’, in the second column title this ‘Critical Limit’ and the final column title this ‘Justification’. Complete the table based on the critical limits that you have identified at each process step.

This table should then be reviewed on a minimum annual basis to ensure that there has been no changes. I will be put a link in the episode transcription so you can view a sample.

Wrap Up

A final quick reminder about my presentation on food safety live this week. If you haven’t already registered, I urge you to do so as places are filling up fast. If for whatever reason you can’t make it, there will be a recording of the webinar available a couple of days later.

That wraps up another episode of HACCP Mentor Review, I am Amanda Evans and until next time, have a great week.

Let me know if you have a question or to give feedback on this post. Please leave a comment below.

Can anyone give me an idea on how to control foreign matter objects into food processing area?

thankz!

Rgds/ QAD

There are lots of ways to control foreign matter but are going to very specific to your manufacturing site. The most logical control is exclusion of particular items. If you cannot exclude items, you can then use inspection/checking activities to ensure the items are intact, not broken and located in their designated areas.