Having a clean production environment is one of the basic fundamentals for good food safety. Surprisingly, it still amazes me how so many food businesses cannot get this right. This really basic video serves as a good little refresher for you and your staff.

Watch Video

Cleaning and Sanitising Food equipment

I have previously posted on what the definition of clean is but I also wanted to talk about the different methods of sanitising. The purpose of sanitising is to reduce bacteria to a safe level. It does not completely remove all risk but just provides a reduction to safer levels. You can’t effectively sanitise a visually ‘unclean’ surface. So the key is to make sure that you cannot see any muck, filth, dirt, dust, build-up, food scraps on the surface that you want to sanitise. The most common forms of sanitising is by use of formulated chemicals or use of hot water.

Common methods of sanitising

- Soak items to be sanitised in hot water for a least 30 seconds. The water temperature should be a minimum of 77oC (171oF).

- Applying a food grade chemical sanitiser used in accordance with the manufacturer’s instructions.

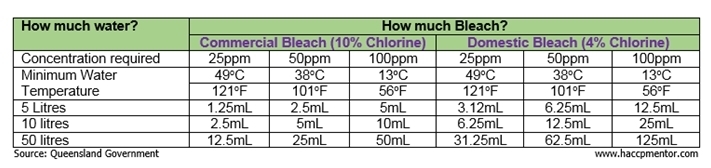

- By soaking the cleaned item in water that contains bleach. The water temperature used in the method will vary depending on the actual concentration of the bleach that you have used. I have included a Sanitising Solution below with temperature and bleach concentrations.

Bleach Concentrations and Temperature requirements

Cleaning Training

If you want to check out more, our Food safety and quality compliance refresher covers the basics of cleaning.

I love the topic on how to handle chemicals in the food business great information thank you for sharing. Joe